In today’s fast-paced industrial environment, ensuring the safety of all employees is paramount. One critical area often overlooked is the proper use and handling of electrical pallet jacks. These machines are essential for efficiently moving heavy loads, but without proper training, they can pose significant risks to operators and other workers. This is why comprehensive Electrical Pallet Jack Safety Training is crucial for maintaining a safe and productive workplace.

Understanding the Risks

Electrical pallet jacks, while incredibly useful, can be hazardous if not used correctly. The primary risks associated with their use include:

Crushing Injuries: These can occur if the operator or nearby workers get caught between the pallet jack and a stationary object or another piece of equipment.

Collisions: Inadequate training can lead to collisions with walls, machinery, or other workers, resulting in damage and potential injuries.

Load Instability: Improper loading techniques can cause the load to shift or fall, endangering the operator and others nearby.

Ergonomic Issues: Incorrect handling can lead to musculoskeletal injuries due to repetitive strain or improper lifting techniques.

Key Components of Safety Training

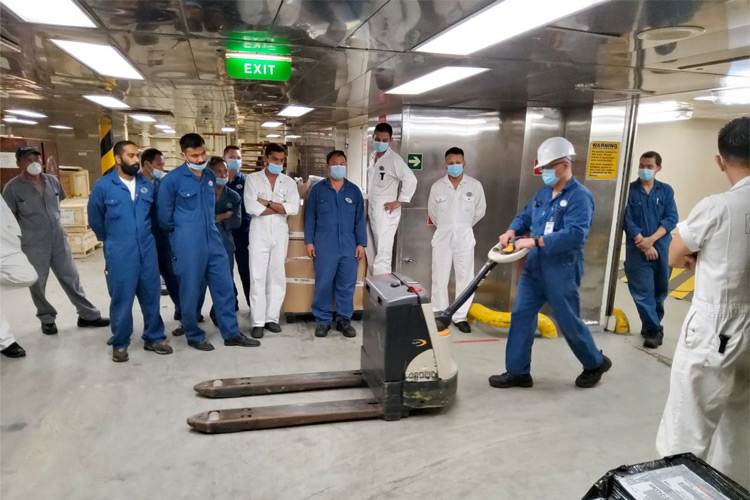

Effective safety training programs cover several essential aspects to ensure that operators can use electrical pallet jacks safely and efficiently. Key components include:

Understanding the Equipment: Familiarizing operators with the specific model of electrical pallet jack they will be using, including its features, controls, and limitations.

Pre-Operational Checks: Teaching operators to perform thorough inspections before each use, checking for any damage, leaks, or malfunctioning parts.

Safe Operating Procedures: Instructing operators on safe driving practices, including maintaining a clear view, using proper speed, and navigating through tight spaces.

Load Handling: Training on correct loading and unloading techniques to ensure stability and prevent load shifting.

Emergency Protocols: Educating operators on how to respond in case of an emergency, such as equipment failure or a workplace accident.

Benefits of Proper Training

Investing in thorough electrical pallet jack safety training brings numerous benefits, including:

Reduced Accident Rates: Well-trained operators are less likely to be involved in accidents, leading to a safer workplace.

Increased Productivity: Proper training ensures that operators can handle pallet jacks efficiently, improving overall productivity.

Lower Maintenance Costs: Trained operators are more likely to conduct regular maintenance checks and use the equipment correctly, reducing wear and tear and lowering repair costs.

Compliance with Regulations: Comprehensive training helps businesses comply with occupational safety regulations, avoiding potential fines and legal issues.

Think Safety Always: Your Partner in Safety Training

For businesses looking to enhance their safety protocols, Think Safety Always offers top-notch Electrical Pallet Jack Safety Training. Their experienced trainers provide practical, hands-on instruction tailored to your specific needs, ensuring that your team is well-equipped to operate electrical pallet jacks safely. By choosing Think Safety Always, you can rest assured that your workplace will be safer, more efficient, and fully compliant with safety standards. Order the course here.