Electric pallet jacks are widely used to lift palletized goods a few inches off the ground to transport them to another location. Although their function is simple, there are many potential hazards to be aware of during operation. That’s why it’s vital that all operators are trained in proper electric pallet jack safety and operating practices.

This pallet jack training course is designed to meet the requirements outlined by OSHA’s Powered Industrial Trucks Standards (1910.178 (l)). By adhering to these standards, operators are instructed in the best electric pallet jack safety practices. This helps reduce the risk of incidents while on the job, keeping operators and surrounding personnel safe.

Electrical pallet jack training topics:

- Types of pallet jacks

- Differences between motorized and standard pallet jacks

- Walk-behind units

- Ride-on units

- Safe operating procedures

- Pre-use inspection & safety checklists

- Picking a load up

- Traveling with a load

- Setting a load down

- Parking and safe storage

Upon completion of this hands-on training, operators will be able to:

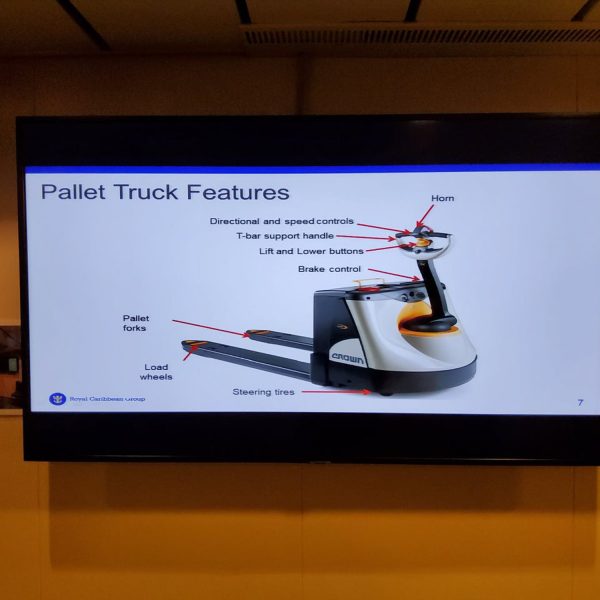

- Identify the basic controls of a walk-behind and stand-on pallet jack.

- Explain what to look for when performing a pre-use inspection.

- Locate and describe how to use various safety features and emergency stop functions.

- Describe how to safely operate a motorized pallet jack. This includes picking the load up, transporting it, setting it down, and then parking the pallet jack when finished.

- Recognize common hazards associated with motorized pallet jacks and ways to avoid them.